Industrial Valve & Instrumentation Sales

TEMPERATURE MEASUREMENT

What is a Thermocouple?

A Thermocouple is a sensor used to measure temperature. Thermocouples consist of two wire legs made from different metals. The wires legs are welded together at one end, creating a junction. This junction is where the temperature is measured. When the junction experiences a change in temperature, a voltage is created. The voltage can then be interpreted using thermocouple reference tables to calculate the temperature.

There are many types of thermocouples, each with its own unique characteristics in terms of temperature range, durability, vibration resistance, chemical resistance, and application compatibility. Type J, K, T, & E are “Base Metal” thermocouples, the most common types of thermocouples. Type R, S, and B thermocouples are “Noble Metal” thermocouples, which are used in high temperature applications.

Thermocouples are used in many industrial, scientific, and OEM applications. They can be found in nearly all industrial markets: Power Generation, Oil/Gas, Pharmaceutical, BioTech, Cement, Paper & Pulp, etc. Thermocouples are also used in everyday appliances like stoves, furnaces, and toasters.

Thermocouples are typically selected because of their low cost, high temperature limits, wide temperature ranges, and durable nature.

Thermocouples are available in two basic constructions:

a) Wire and bead type.

b) Metal sheathed mineral insulated type.

Various constructions are available, depending on

process connections.

THERMOWELLS

Thermowells are used to provide an isolation between a temperature sensor and the environment, either liquid, gas or slurry. A thermowell allows the temperature sensor to be removed and replaced without compromising either the ambient region or the process.

Care must be taken in determining the material used for the thermowell as well as other factors. Thermo Sensors offers design assistance that includes pressure, temperature and or corrosion as well as vibration effects of the fluids. This vibration can cause well stem failure.

Thermo Sensors thermowell materials include:

• Carbon Steel

• 304 & 316 Stainless Steel

• Monel

• Brass

Thermowells are used to shield thermocouple elements against mechanical damage and corrosion. Many variations are available in a variety of materials to meet individual job specifications.

The chemical and physical properties of all standard bar stock materials are rigidly controlled. All bar stock wells are drilled by the gun drilling process. Use of specially designed and constructed measuring equipment enables standard guaranteed bore concentricity to be within ± 10% of wall thickness. Internal threads are within 1/2 turn of standard plug gauge. External threads are within 1/4 turn of standard ring gauge.

If required by customer, your thermowells undergo an internal hydrostatic test as a final precaution against pressure failure. Test pressures and duration are determined by the customer. Radiograph and other tests can be performed, and results furnished upon request.

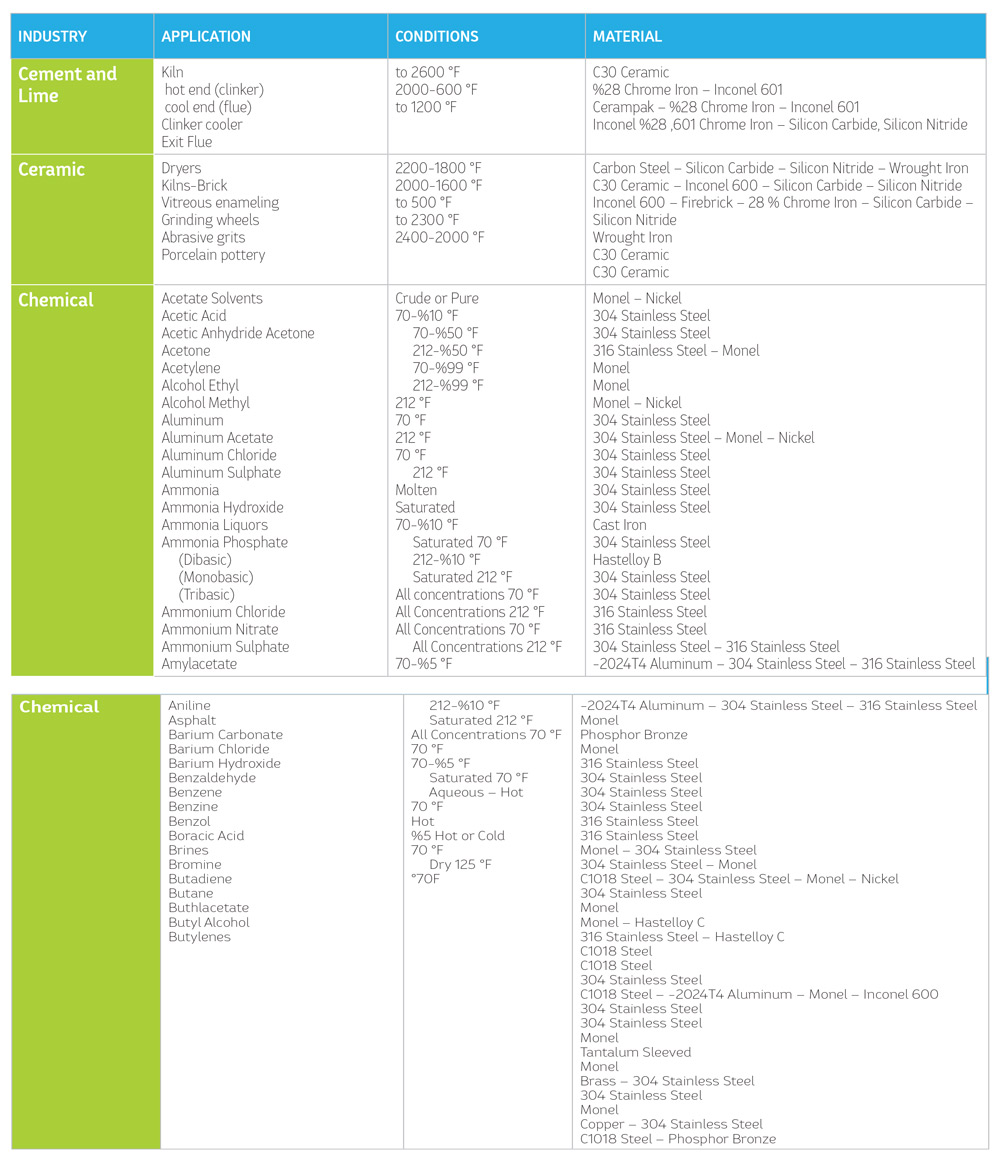

A variety of alloys suitable for every thermowell requirement is available. Thermowell material should be selected for ability to withstand the process environments, high thermal conductivity and low porosity to gases.

Industrial Valve & Instrumentation Sales

Email: graecor@mweb.co.za • Tel: 031 208 8041

BBBEE CONTRIBUTOR

“Life-Line Psalm 23”